Home / All / STEEL PRODUCTS / Aluminized Steel /

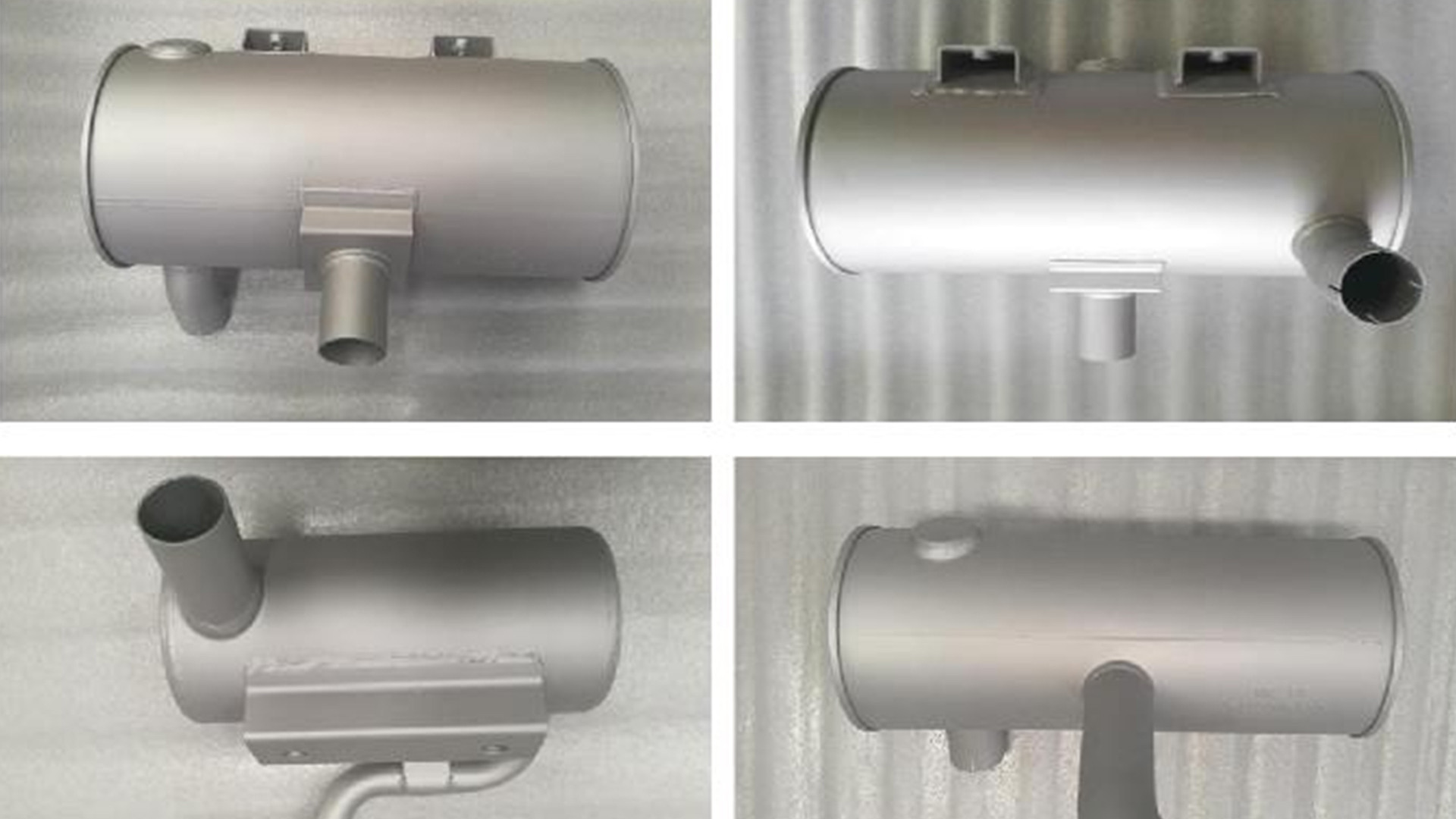

Aluminized Steel Tube/pipe suitable for heat exchange pipes, exhaust pipes, high-temperature resistant pipelines, etc

Can't find what you are looking for?providing the solution of the industrial raw materials based on the steel

Contact us for free modeling

Just fill-in the form below and we will response to you within 12 hours.

- Tel

- *Title

- *Content

Aluminized Steel Tube/pipe suitable for heat exchange pipes, exhaust pipes, high-temperature resistant pipelines, etc

Detail Information

Aluminized Steel Tube

The coating of aluminum-silicon alloy reinforces steel strength with heat and corrosion protection.

ASTM A463 T1 Aluminized steel tubing is mild steel tube that has been hot-dip coated on both sides with an aluminum-silicone alloy.

Our Aluminized Steel Tube's raw material undergoes a continuous hot-dip process, building a coating across every millimeter of the surface.

Hot-dipping results in a tight metallurgical bond between layers of an aluminum-silicon alloy and the tube's steel core.

The final aluminized tube possesses a combination of enhanced properties: the strength of steel sheathed in the corrosion resistance of aluminum and heat protection of aluminum-silicon alloy.

Aluminized steel's heat shield makes it an ideal, cost-effective choice for fabrications exposed to punishing temperatures: automotive exhaust, plus HVAC and equipment, such as water heaters, furnaces heat exchangers, space heaters, ranges and appliances of multiple sizes. It also performs nicely against exposure to salts.

MESCO Advantages

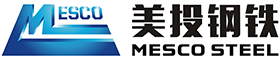

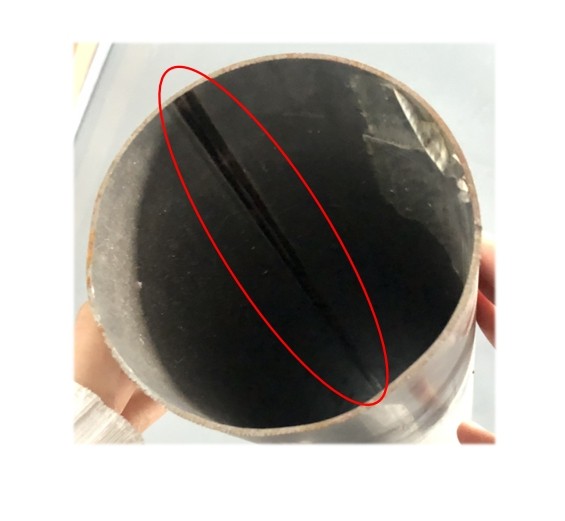

Good welding seam dealing. MESCO use aluminium to fulfill the welding seam while other supplier may use zinc. but aluminium is easier to be fired when we do seam dealing, other supplier use zinc to deceive and also save cost.

Quick release and short delivery time. MESCO is the only one supplier who has own DX53D+AS120 stock with different common thickness.So that we can choose coil with best elongation to make pipe.

Cover all specifications.

Ultrasonic Welder. MESCO only use Panasonic or Ultrasonic welder to deal with welding seam with better performance of flaw detection.

Have rich experience in providing service to several famous vessel brand like KAMAZ, LAND ROVER, TOYOTA, HONDA, etc.

Aluminized Steel Description

| Model NO | DX53D AS120 、 DX54D AS120 |

| Certification | ISO, RoHS, IBR |

| Technique | Cold Rolled |

| Edge | Slit edge |

Test | SGS |

Length | 3000 5800 6000 120000mm |

Specification | 1.0mm 1.2mm 1.5mm |

Origin | China |

Production Capacity | 100000mt |

Standard | ASTM, JIS, GB, AISI, DIN, BS |

Surface Treatment | Coated |

Application | Exhaust Pipe |

Coating | As80 As120 As240 As300 g/㎡ |

Transport Package | Iron Sheet+ Water proof Paper |

Trademark | MESCO STEEL |

Aluminized Steel Tube

DX53D / SA1C

A non-alloy steel grade that belongs to the category of continuous hot-dip coated steel (EN10346:2015).

Feature: A low-carbon steel with a coating of zinc and has a minimum yield strength of 140 MPa.

Performance: Good corrosion resistance, formability, and weldability

DX54D / SA1D

A non-alloy steel grade that is classified under the category of galvanized steel (EN 10346:2015).

Feature: A low-carbon steel with a coating of zinc and has a minimum yield strength of 120 MPa.

Performance: Good corrosion resistance, formability, and weldability, excellent deep-drawing properties, which makes it suitable for use in stamping and forming applications.

| Grade | YS(Mpa) | TS(Mpa) | EL(A80/%)min |

| DX53D | 140-260 | 270-380 | 30 |

| DX54D | 120-220 | 260-350 | 34 |

| DX56D | 120-180 | 260-350 | 37 |

Unit Mass Table For Sheets (kg/㎡)

| Nominal Thickness (mm) | Aluminum coating mass designation | ||||

| 40 | 60 | 80 | 100 | 120 | |

| 0.30 | 2.242 | 2.186 | 2.130 | 2.065 | 2.017 |

| 0.35 | 2.635 | 2.578 | 2.552 | 2.458 | 2.409 |

0.40 | 3.027 | 2.971 | 2.915 | 2.850 | 2.802 |

0.50 | 3.812 | 3.756 | 3.700 | 3.635 | 3.587 |

0.60 | 4.597 | 4.541 | 4.485 | 4.420 | 4.372 |

0.70 | 5.382 | 5.326 | 5.270 | 5.205 | 5.157 |

0.80 | 6.167 | 6.111 | 6.055 | 5.990 | 5.942 |

0.90 | 6.952 | 6.896 | 6.840 | 6.775 | 6.727 |

1.0 | 7.737 | 7.681 | 7.625 | 7.560 | 7.512 |

1.2 | 9.307 | 9.251 | 9.195 | 9.130 | 9.082 |

1.4 | 10.88 | 10.82 | 10.76 | 10.70 | 10.65 |

1.6 | 12.45 | 12.39 | 12.33 | 12.27 | 12.22 |

2.0 | 15.59 | 15.53 | 15.47 | 15.41 | 15.36 |

2.3 | 17.94 | 17.89 | 17.83 | 17.77 | 17.72 |

2.5 | 19.51 | 19.46 | 19.40 | 19.34 | 19.29 |

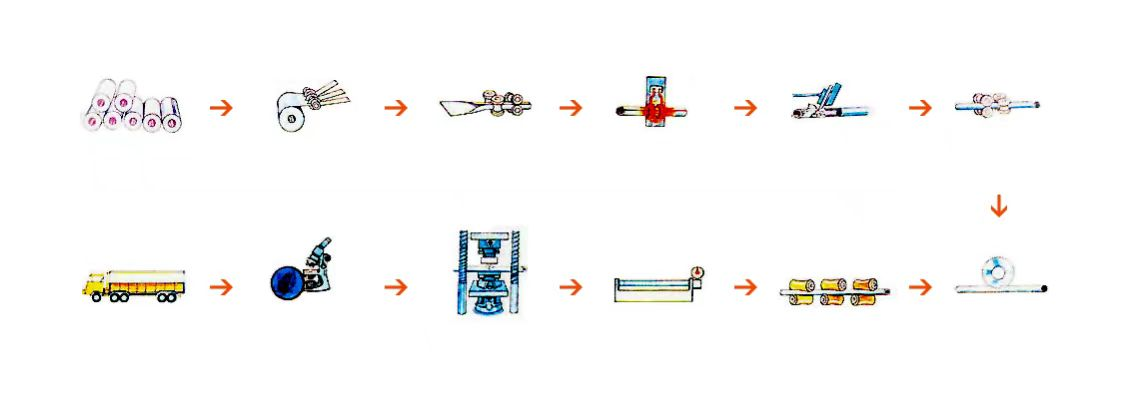

Aluminized Steel Tube Manufacturing Process

WHY DO YOU CHOOSE ALUMINIZED STEEL PIPE INSTEAD OTHER MATERIAL?

1. Corrosion resistance:

Aluminum has good corrosion resistance, and aluminum plated pipes can provide good corrosion resistance. Aluminum coatings can effectively resist the erosion of pipelines by chemicals, oxides, and other corrosion sources, protecting pipelines from corrosion damage. This makes aluminum plated pipes a preferred choice for various harsh environments, such as marine environments, chemical industries, and oil and gas extraction.

2. Lightweight and high-strength:

Compared to other metal materials, aluminum has a lower density and has the advantage of lightweight. The lightweight characteristics of aluminum plated pipes make them more convenient for transportation and installation, reducing the burden on workers. In addition, aluminum pipes have high strength and can withstand large pressure and gravity loads, providing reliable pipeline operation.

3.Excellent thermal conductivity:

Aluminum has excellent thermal conductivity, and aluminum coated pipes can quickly and evenly transfer heat. This makes aluminum plated pipes very suitable for fields that require efficient heat transfer, such as heat exchange equipment and heating systems. By improving the efficiency of heat transfer, aluminum plated tubes can reduce energy consumption and improve equipment performance.

Expensive Raw Material

Aluminized steel is about 130-150 USD/MT higher than ZAM steel, 250-300USD/MT than galvanized steel.

Slow producing speed

For aluminized steel, it can be produced 30 meter/min, but for galvanized steel it is 80 meter/min. The energy consuming is 4 times than that of galvanized steel pipe.

Frequent examination during producing proess

Aluminized steel producing line need test in every producing part, which cause the waste iron rate increases.

High waste iron rate

Using aluminium to fufill the weld seam is easily to be fired, so the waste probality is higher.

High cost of loading

Because of big out diameter, usually it needs divepipe. To avoid abrasion, we wear it with plastic film by manual work, manual work is the highest cost in loading.

The distribution of raw materials produces a lot of waste iron

The stock ususally 1250mm width, which cause lots of waste iron.

Deep Processing

Deep Processing

· Bending

· Punching

· Cutting

· Welding

Aapplication Scenario

Packing And Shipping

DALIAN MESCO STEEL CO.,LTD

Sincere, Professional, Effective, Innovative!

18years 88countries 500+clients

Email :mesco@mescogroup.com.cn

Review

- Loading...

Get Free & Quality Online Consultation

Send us some details about your needs and feel free to ask any questionss. Our sales team will get back to you via email within a day.

Contact us for free modeling

Just fill-in the form below and we will response to you within 12 hours.

- Tel

- *Title

- *Content

navigation

Integrated Building