Home / All / STEEL PRODUCTS / Stainless Steel /

MESCO 304 stainless steel coil 316 stainless steel sheet

Can't find what you are looking for?providing the solution of the industrial raw materials based on the steel

Contact us for free modeling

Just fill-in the form below and we will response to you within 12 hours.

- Tel

- *Title

- *Content

MESCO 304 stainless steel coil 316 stainless steel sheet

Detail Information

Stainless Steel Sheet

Stainless steel plate is an alloy steel with smooth surface, high weldability, corrosion resistance, polishability, heat resistance, corrosion resistance and other characteristics. It is widely used in various industries and is an important material in modern industry. Stainless steel is divided into austenitic stainless steel, ferritic stainless steel, martensitic stainless steel, and duplex stainless steel according to the structure state.

Stainless Steel Sheet Grades

| Item | Stainless steel sheet(cold rolled or hot rolled) |

| Thinckness | Cold rolled:0.15mm-10mm |

| Hot rolled: 3.0mm-180mm | |

| Widthness | 8-3000mm |

Length | 1000mm-11000mm or as customer' s requirement |

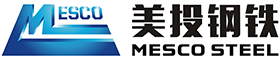

Finish | 2B, 2D, 4B, BA, HL, MIRROR, brush, NO. 1-NO. 4, 8K, and so on. |

Standard | ASME, ASTM, EN, BS, GB, DIN, JIS etc |

Price term | Ex-Work,FOB,CNF,CFR,CIF,FCA etc |

Payment term | TT, L/C, trade assurance etc |

Material | mainly201, 202, 304, 304L, 304H, 316, 316L,316Ti,2205, 330, 630, 660, 409L, 321, 310S, 410, 416, 410S, 430, 347H, 2Cr13, 3Cr13 etc |

300series:301,302,303,304,304L,309,309s,310,310S,316,316L,316Ti,317L,321,347 | |

200series:201,202,202cu,204 | |

400series:409,409L,410,420,430,431,439,440,441,444 | |

Others:2205,2507,2906,330,660,630,631,17-4ph,17-7ph, S318039 904L,etc | |

Duplex stainless steel:S22053,S25073,S22253,S31803,S32205,S32304 | |

Special Stainless Steel:904L,347/347H,317/317L,316Ti,254Mo | |

Application range | Escalator, Elevator, Doors |

Furniture | |

Production tools, Kitchen appliances, freezers, cold rooms | |

Auto Parts | |

Machinery and Packaging | |

Equipment and Medical devices |

Classification of Stainless Steel

| iron + carbon = steel | ||||

| + chromium = stainless steel (at least 10.5% chromium) | ||||

| | martensitic alloys | austenitic alloys | duplex alloys | precipitation hardening alloys |

| ferritic alloys | carbon(0.10-1.2%) +chromium (12-18%) | ++chromium(16%) +nickel(8%) | +chromium (19%) +molybdenum +small amount of nickel | +chromium +nickel +copper/or other elements |

Performance Characteristics

| alloy group | magnetic response | work hardening rate | corrosion resistance | hardenable | ductility | high temperature resistance | low temperature resistance | weldability |

| austenitic | generally no | very high | high | by cold work | very high | very high | very high | very high |

duplex | yes | medium | very high | no | medium | low | medium | low |

ferritic | yes | medium | medium | no | medium | high | low | low |

martensitic | yes | medium | medium | quench & temper | low | low | low | low |

| precipitation hardening | yes | medium | medium | age harden | medium | low | low | high |

Classification of Stainless Steel

| Austenitic Stainless Steels | |||||||||

| AISI | DIN | C | Cr | Ni | Mo | N | Mn | Cu | Other |

| 201 | 1.4372 | 0.15 | 16.0-18.0 | 1.25-5.5 | - | 0.25 | 5.50-7.50 | 0.80 | - |

301 | 1.4310 | 0.15 | 16.0-18.0 | 6.0-8.0 | - | 0.10 | 2.00 | - | - |

304L | 1.4307 | 0.030 | 17.5-19.5 | 8.0-12.0 | - | 0.10 | 2.00 | - | - |

321 | 1.4541 | 0.08 | 17.0-19.0 | 9.0-12.0 | - | 0.10 | 2.00 | - | Ti5X(C+N) |

309 | 1.4828 | 0.08 | 22.0-24.0 | 12.0-15.0 | - | - | 2.00 | - | - |

310S | 1.4845 | 0.08 | 24.0-26.0 | 19.0-22.0 | - | - | 2.00 | - | - |

316L | 1.4404 | 0.030 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | 0.10 | 2.00 | - | - |

| Ferritic Stainless Steels | |||||||||

| AISI | DIN | C | Cr | Ni | Mo | N | Mn | Cu | Other |

| 409 | 1.4512 | 0.030 | 10.5-11.7 | 0.50 | - | 0.030 | 1.0 | - | Ti 6X(C+N) to 0.5Cb0.17 |

430 | 1.4016 | 0.12 | 16.0-18.0 | 0.75 | - | - | 1.0 | - | - |

434 | 1.4113 | 0.12 | 16.0-18.0 | - | 0.75-1.25 | - | 1.0 | - | - |

444 | 1.4521 | 0.025 | 17.5-19.5 | 1.0 | 1.75-2.50 | 0.035 | 1.0 | - | Ti+Cb[0.20+4(C+N] to 0.80max. |

| Martensitic Stainless Steels | |||||||||

| AISI | DIN | C | Cr | Ni | Mo | N | Mn | Cu | Other |

| 410 | S41000 | 0.08-0.15 | 11.5-13.5 | 0.75 | - | - | 1.0 | - | - |

420 | S42000 | 0.15min. | 12.0-14.0 | 0.75 | 0.50 | - | 1.0 | - | - |

440A | S44002 | 0.60-0.75 | 16.0-18.0 | - | 0.75 | - | 1.0 | - | - |

440C | S44004 | 0.95-1.20 | 16.0-18.0 | - | 0.75 | - | 1.0 | - | - |

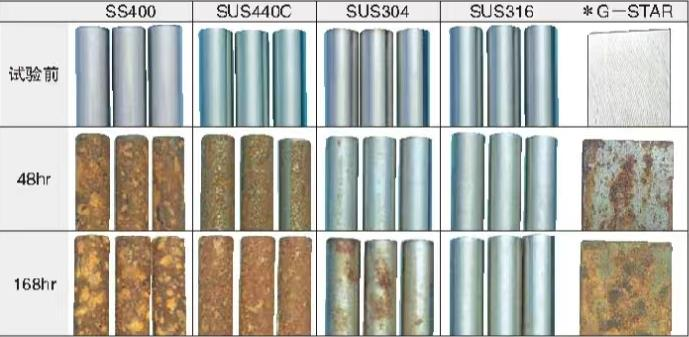

Conduct composite corrosion test

according to JsH8502 cycle test method

Test Conditions: 8 hours is one cycle

1 salt water spray test (5% Na35 ℃) 2hr

2 dry (60 ℃) 4hr

3 wet (95% RH.35 ℃ 3hr

Corrosion Resistance:SUS316>SUS304>SUS440C>SS400

Stainless Steel Classify

Stainless Steel Weld Pipe

Stainless Steel Seamless Pipe

Stainless Steel Seamless Pipe

Stainless Steel Pipe Processing Services

Aapplication Scenario

Packing And Shipping

Processing Service

Email : mesco@mescogroup.com.cn

Sincere, Professional, Effective, Innovative!

18years 88countries 500+clients

Review

- Loading...

Get Free & Quality Online Consultation

Send us some details about your needs and feel free to ask any questionss. Our sales team will get back to you via email within a day.

Contact us for free modeling

Just fill-in the form below and we will response to you within 12 hours.

- Tel

- *Title

- *Content

navigation

Integrated Building